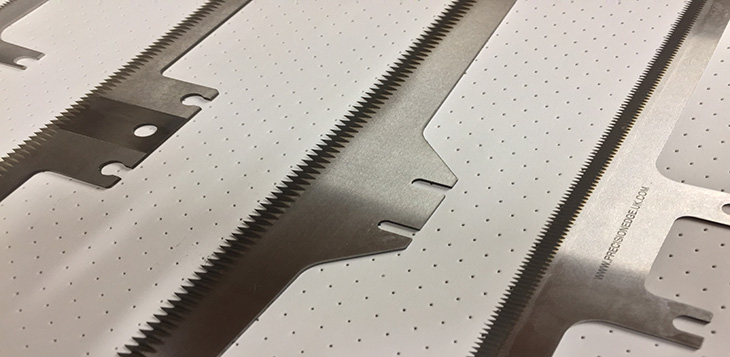

Steel and Heat Treatments for Knives

The heat treating of steel tools is the main factor which separates them from the everyday material. On a molecular level, at high temperature carbon is dissolved from its resident carbides and becomes structural, adding to the strength and hardness of the steel. The tool is them tempered to achieve the desired balance between hardness and toughness.

The quality of the starting material and the expertise of the heat treatment process are the two elements which determine the final characteristics of the material. At Precision Edge we have perfected our machine knife heat treatment operations over the course of many years. We use these skills when manufacturing our own blades, and provide a heat treatment service for our customers.

We also maintain a close working relationships with several of Europe’s leading steel producers, in order to offer our customers the very best materials for every machine blade application. From D2 HC/HC tool steel, to M2 HSS, CS100, and 420/440 stainless, each type is tightly quality controlled and the excellent wear characteristics of these types mean we can offer a lifetime materials guarantee on every blade. Need something even tougher? Our powder metallurgy steels are manufactured using advanced technology which allows fine control over their chemical composition. This makes them easier to process and optimises blade life.

When a carefully formulated steel is subjected to just the right treatments, the result is a superior quality machine knife which will equal or surpass OEM products in terms of performance and longevity. The third piece to the puzzle is our high performance coatings, including titanium nitride, titanium aluminium nitride and nitron MC. We also offer cryogenic low-temperature treatments for component stabilization.

Thanks to our team of expert technicians, we can make machine knives which will exceed your expectations for any process. Contact us to learn more.